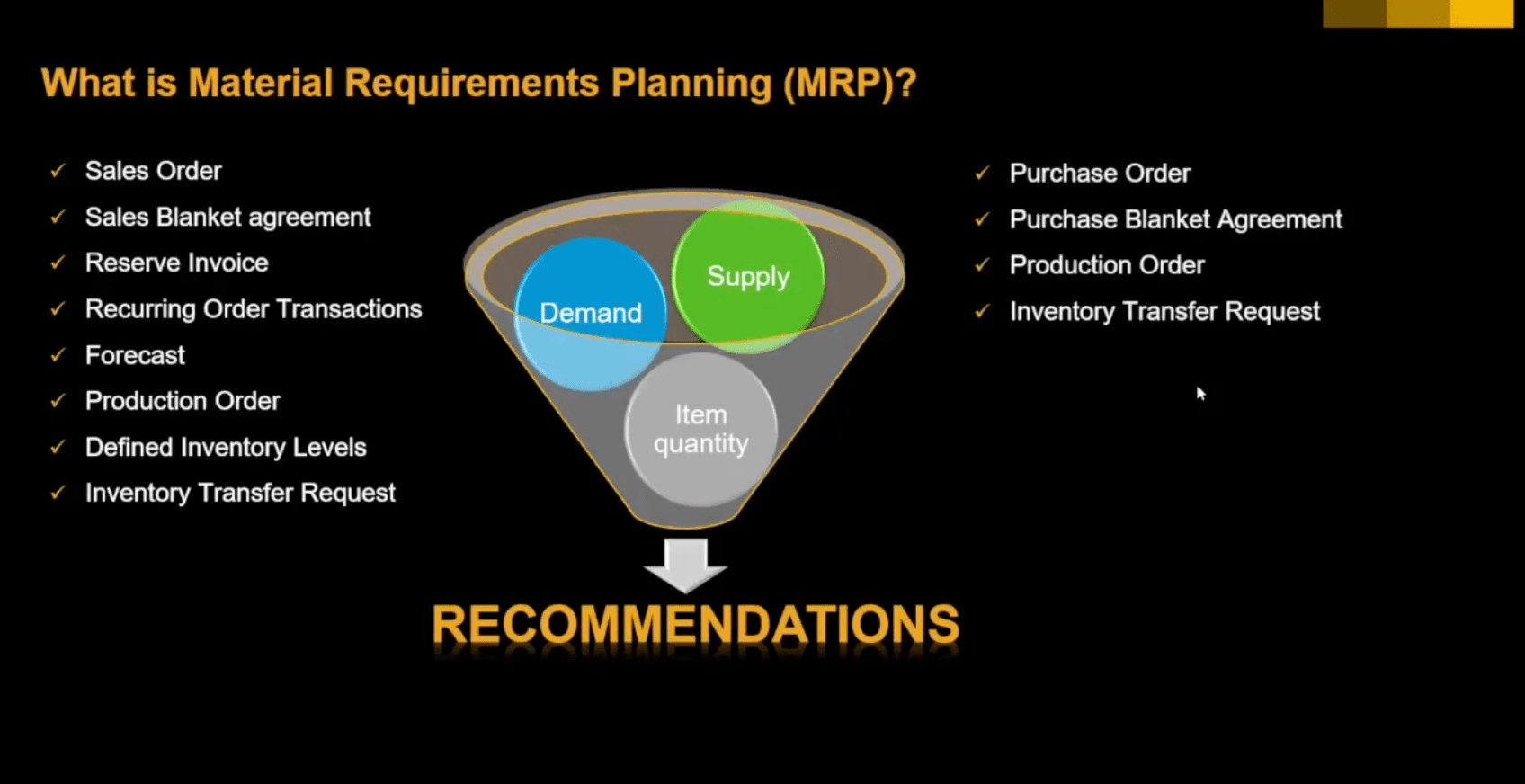

What Is Mrp Mean Definition of MRP MRP is a system designed to plan manufacturing production It identifies necessary materials estimates quantities determines when materials will be required to meet the production schedule and manages delivery timing with the goal of meeting demands and improving overall productivity

Material Requirements Planning MRP is a standard supply planning system to help businesses primarily product based manufacturers understand inventory requirements while balancing supply and demand Businesses use MRP systems which are subsets of supply chain management systems to efficiently manage inventory schedule production and Material requirements planning MRP is a production planning scheduling and inventory control system used to manage manufacturing processes Most MRP systems are software based but it is possible to conduct MRP by hand as well An MRP system is intended to simultaneously meet three objectives Ensure raw materials are available for production and products are available for delivery to

What Is Mrp Mean

What Is Mrp Mean

http://www.qstockinventory.com/wp-content/uploads/2015/02/bigstock-Engineer-Ordering-To-Worker-59724149.jpg

What Is MRP How Does It Work MRP System Flowlens

https://flowlens.com/wp-content/uploads/2021/02/clayton-cardinalli-hkJNx0EDbjE-unsplash-2048x1365.jpg

What Does LRP And MRP Mean In Baseball Baseball Scouter

https://baseballscouter.com/wp-content/uploads/2022/01/What-Does-LRP-and-MRP-Mean-in-Baseball.jpg

Material requirements planning MRP is a production planning and inventory control system An MRP integrates data from production schedules with that from inventory and the bill of materials BOM to calculate purchasing and shipping schedules for the parts or components required to build a product MRP converts the master schedule of production into a detailed schedule so that you can purchase raw materials and components Used mostly in the manufacturing and fabrication industries this system is a push type of inventory control meaning that organizations use forecasting to determine the customer demand for products

Material requirements planning MRP is a system businesses use to calculate and manage the cost of all the raw materials and components that go into making a product Materials might be things like wood plastic paint metal or fabric Components are pre fabricated parts made by third party manufacturers such as microchips zippers screws MRP or Material Requirements Planning is a software based integrated inventory and supply management system designed for businesses It is used to plan manufacturing procurement and delivery schedules for components materials and finished products based on customer demand The main objective of MRP is to ensure that materials and

More picture related to What Is Mrp Mean

![]()

Why MRP For Small Businesses And Mid Sized Companies

https://cdn.shortpixel.ai/client/q_lossless,ret_img,w_512/https://pass-port.com/wp-content/uploads/2018/08/mrp.png

What Is MRP YouTube

https://i.ytimg.com/vi/M2-Jz-6p4Ro/maxresdefault.jpg

What Is MRP And Do You Need It

https://erpnext.com/files/what-is-mrp-cover.jpg

What does MRP mean in manufacturing Material Requirements Planning MRP in manufacturing is a production planning scheduling and inventory control system used to manage manufacturing processes It is a systematic approach to calculating the materials and components required to manufacture a product MRP integrates data from production Material Requirements Planning MRP is a computerized inventory management system specifically crafted to aid businesses in making production schedules and planning orders for demanded items raw materials components etc MRP process can be divided into the following key stages Determining Requirements to Fulfill Demand

An MRP system is the central production software that manufacturing companies use to manage optimize schedule and automate large parts of the manufacturing process This software integrates key aspects of manufacturing into a single productivity suite including production inventory management order management procurement planning MRP enables businesses to maintain an optimal level of inventory by aligning it with production needs This prevents overstocking and stockouts ensuring that materials are available when needed The result is a streamlined and efficient inventory management system 2 Enhanced Production Scheduling

What Is Mrp What Is And MRP 2019 01 19

https://www.leveragebusinessone.com.au/wp-content/uploads/2018/02/Screen-Shot-2018-02-02-at-8.59.02-am.png

What Is MRP YouTube

https://i.ytimg.com/vi/vldhPwgJGYI/maxresdefault.jpg

What Is Mrp Mean - MRP Meaning Background and History MRP stands for materials requirement planning This concept requires creating material plans and production schedules based on the lead times of a supply chain MRP answers three questions what is needed how much is needed and when is it needed