What Does Mrp Mean In Manufacturing The Bottom Line Material requirements planning MRP is a software based integrated inventory and supply management system that companies use to estimate quantities of raw materials and schedule

1 Key Concepts in MRP a MRP Definition Material Requirements Planning MRP is a computerized inventory and production planning system used to manage manufacturing processes It ensures that materials are available for production finished goods are available for delivery and inventory is kept at optimal levels b Objectives of MRP Material requirements planning MRP is a production planning scheduling and inventory control system used to manage manufacturing processes Most MRP systems are software based but it is possible to conduct MRP by hand as well An MRP system is intended to simultaneously meet three objectives Ensure raw materials are available for production and products are available for delivery to

What Does Mrp Mean In Manufacturing

What Does Mrp Mean In Manufacturing

https://i.ytimg.com/vi/L0EoX5BE8Nk/maxresdefault.jpg

MRP I Vs MRP II Difference Between Material Requirement Planning

https://i.ytimg.com/vi/v7l4hyeMd0E/maxresdefault.jpg

What Is MRP Material Requirements Planning Why Is It Important

https://i.ytimg.com/vi/Dis3UYcEXVw/maxresdefault.jpg

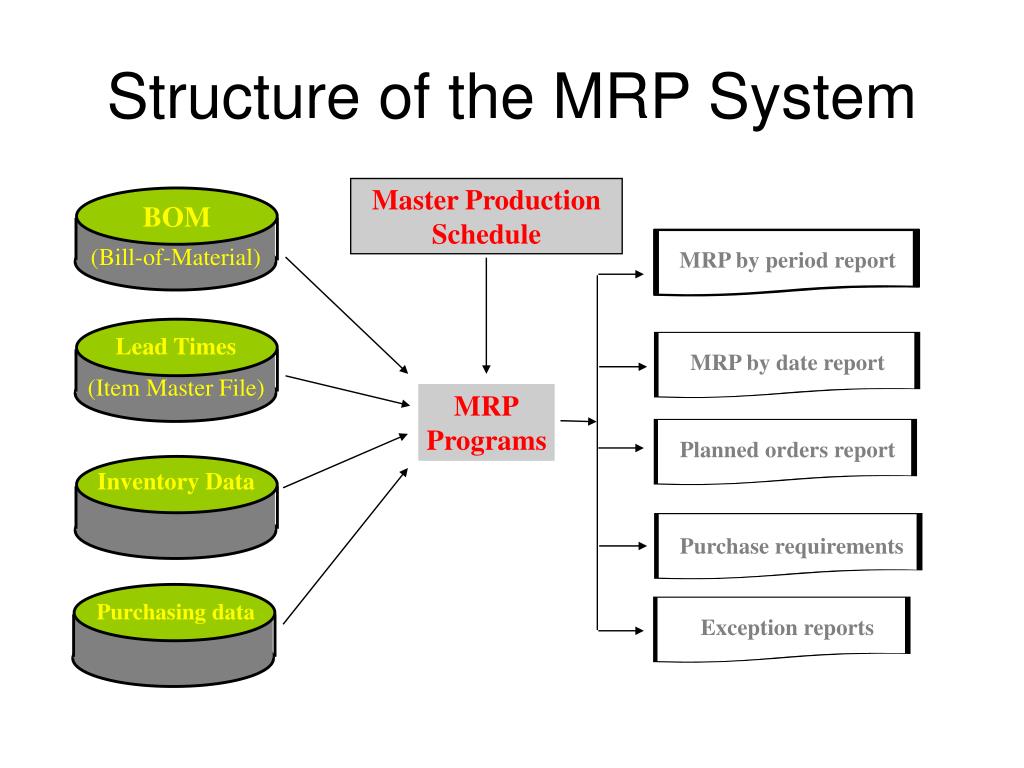

An MRP system is the central production software that manufacturing companies use to manage optimize schedule and automate large parts of the manufacturing process This software integrates key aspects of manufacturing into a single productivity suite including production inventory management order management procurement planning An extension of MRP developed by Wight in 1983 and called manufacturing resource planning MRP II broadened the planning process to include other resources in the company such as financials and added processes for product design capacity planning cost management shop floor control and sales and operations planning among many others

What does MRP mean MRP stands for material requirements planning It helps businesses plan track and manage their materials throughout the manufacturing process MRP systems analyze factors such as production schedules lead times inventory levels and demand forecasts They use this information to generate accurate material requirements Manufacturing companies rely heavily on MRP as the supply planning system to plan and control inventory scheduling and production but MRP is also relevant in many other industries from retail to restaurants to create balance between supply and demand MRP Steps and Processes The MRP process can be broken down into four major steps

More picture related to What Does Mrp Mean In Manufacturing

23 01 MRP Material Requirement Planning Part 1 MRP Type PD And VB

https://i.ytimg.com/vi/NYmpR1dQauw/maxresdefault.jpg

What Is The Material Requirement Planning MRP MRP Process YouTube

https://i.ytimg.com/vi/u3P6YMI5Ah0/maxresdefault.jpg

How To Calculate Price To Stockist PTS And Price To Retailers PTR

https://i.ytimg.com/vi/S3LP-Ph71TU/maxresdefault.jpg

What does MRP mean The term MRP stands for material requirements planning It is a methodology first developed in the late 1960s for calculating the raw material and other requirements that are necessary for manufacturing products What does MRP mean in manufacturing Material Requirements Planning MRP in manufacturing is a production planning scheduling and inventory control system used to manage manufacturing processes It is a systematic approach to calculating the materials and components required to manufacture a product

[desc-10] [desc-11]

MRP Type PD Material Requirement Planning By Sales Order 52 OFF

https://cdn.mindmajix.com/blog/images/what-is-sap-mrp-060623.png

Mrp

https://image.slideserve.com/315548/structure-of-the-mrp-system-l.jpg

What Does Mrp Mean In Manufacturing - [desc-13]