What Is An Mrp Controller The MRP controller is a person or a group of persons responsible for monitoring material availability You can use the number entered here for example to select the planning results per MRP conroller Every material that is relevant to the planning run must be assigned an MRP controller number in the material master record

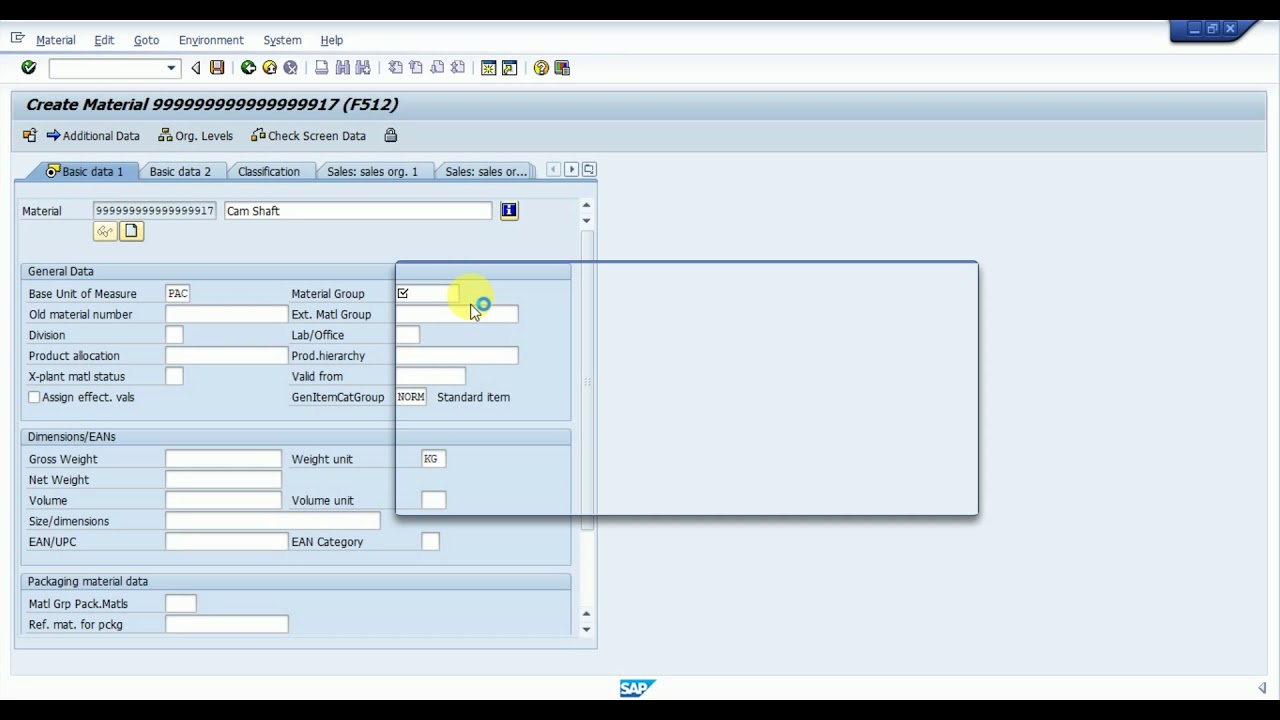

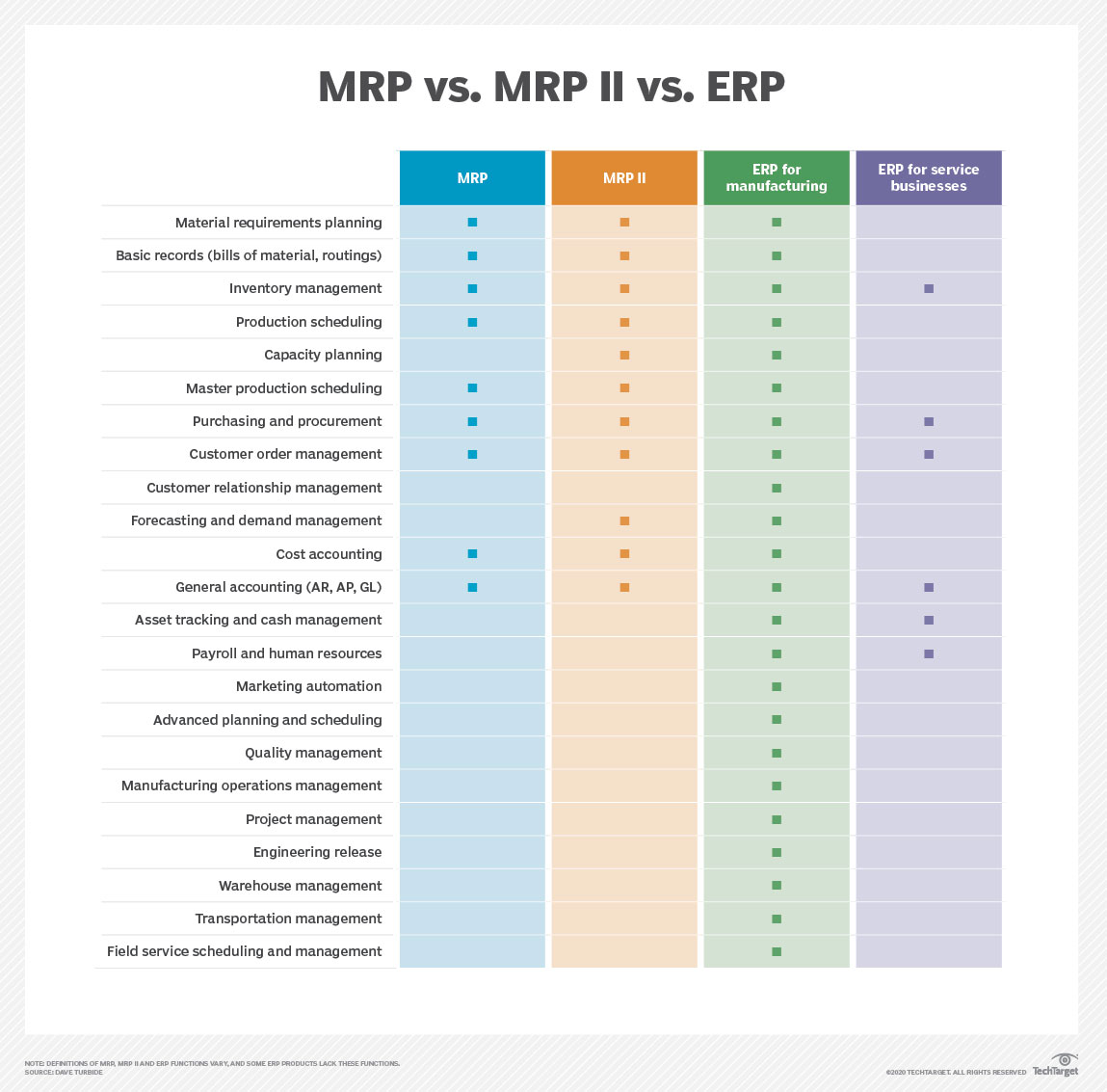

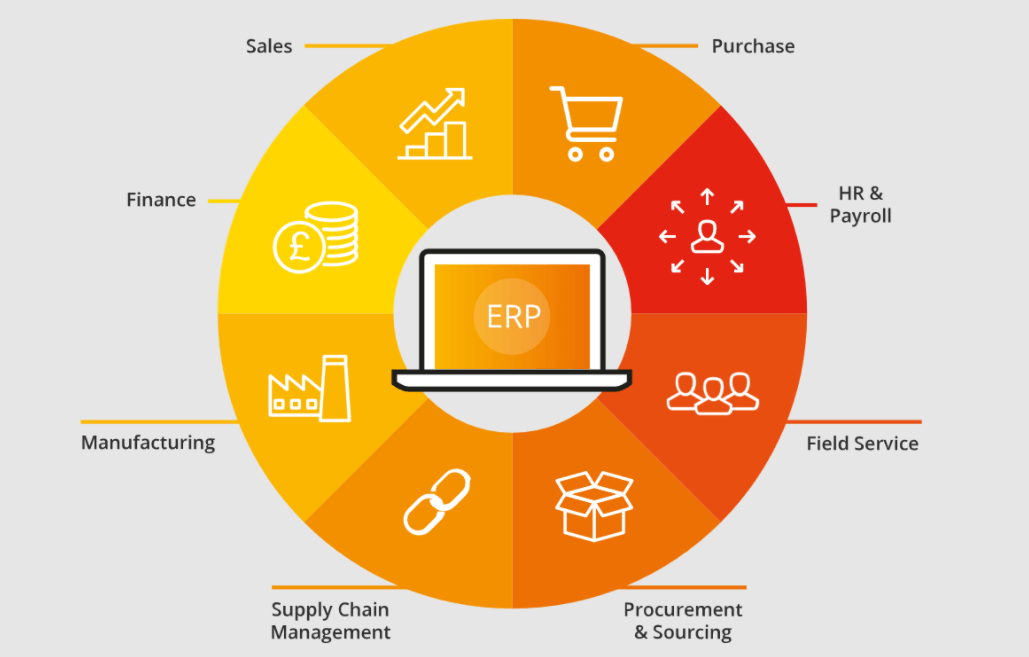

MRP is a planning and control system for the resources in a company and was essentially the harbinger of ERP systems to come ERP is a solution for the enterprise as a whole with more functionality built in extending the concepts of MRP and MRP II All the functions in an enterprise are tightly integrated including internal and external Click on the New Entries icon to define new SAP MRP controllers as per your business requirements Update the following information Plant Update your plant key in the plant field MRP controller Enter MRP key and description Telephone Update the telephone number for contact After maintaining all the mandatory fields click on save to save the configured data

What Is An Mrp Controller

What Is An Mrp Controller

https://i.ytimg.com/vi/JZxy8gk_kDU/maxresdefault.jpg

Total Planning Using MRP Controller SAP Blogs

https://blogs.sap.com/wp-content/uploads/2014/02/untitled_1_397733.png

ERP Vs MRP What Is The Difference Between ERP And MRP

https://www.magestore.com/wp-content/uploads/2021/09/what-is-MRP.png

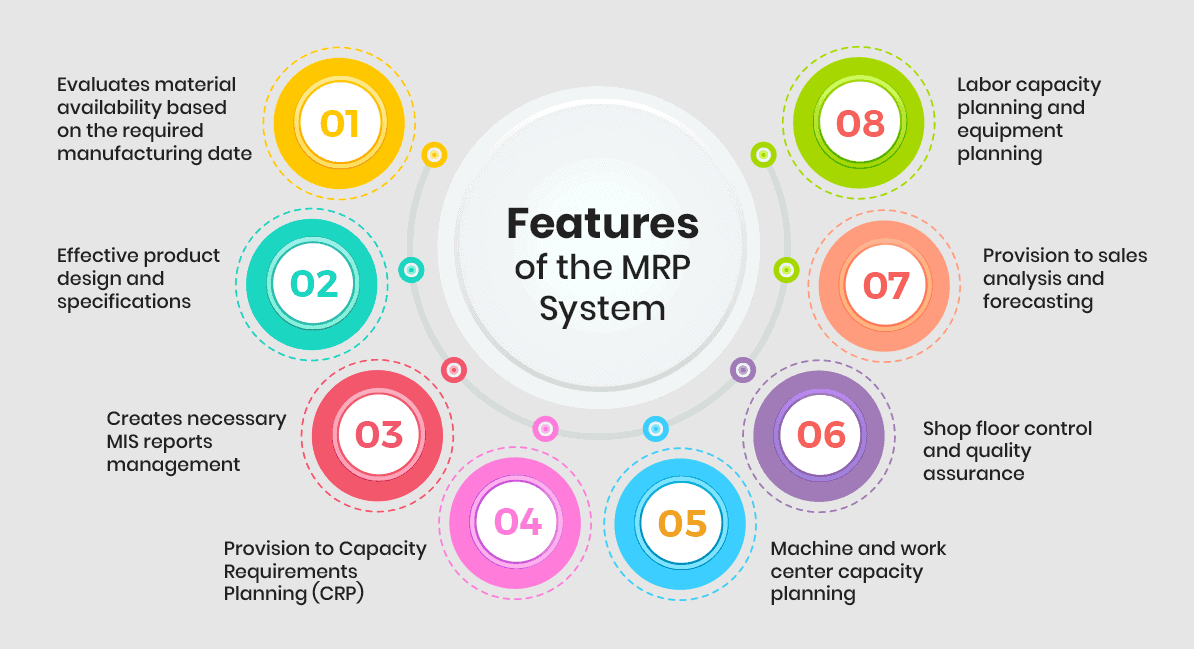

MRP controller is a person or a group of persons responsible for the monitoring of material availabilty He ensures that right quanity of materials are available in right quantity for the production process to run smoothly You can define MRP controller by Spro ProductionMaterial requirement planningmaster data define mrp controller Regards Definition of MRP MRP is a system designed to plan manufacturing production It identifies necessary materials estimates quantities determines when materials will be required to meet the production schedule and manages delivery timing with the goal of meeting demands and improving overall productivity

The worklist of the MRP controller is in the form of a tree on the left optional The header with the material number is above the list More information displays above the header details The list contains the individual MRP elements and the corresponding available quantities Material requirements planning MRP is a production planning and inventory control system An MRP integrates data from production schedules with that from inventory and the bill of materials BOM to calculate purchasing and shipping schedules for the parts or components required to build a product

More picture related to What Is An Mrp Controller

Difference Between MRP Vs MRP II Vs ERP OptiProERP 2022

https://www.optiproerp.com/wp-content/uploads/MRP-vs-MRP-II-vs-ERP.jpg

ERP Vs MRP What Is The Difference Between ERP And MRP

https://www.magestore.com/wp-content/uploads/2021/09/what-is-ERP.png

What Is MRP And Do You Need It

https://erpnext.com/files/what-is-mrp-cover.jpg

MRP is a supply chain planning process used with other planning processes such as Demand Planning Supply Planning Sales Operations Planning Production Planning and Transportation Planning all of which are used to manage the supply chain activity of the enterprise MRP is the process of matching enterprise wide supply with actual and From a business user standpoint the MRP controller executes MRP run in SAP S 4HANA system which considers different stock types of inventory pending material receipts Planned orders production orders purchase requisitions purchase orders stock transfer reservations and delivery schedule lines and material requirements such as Sales

Materials Requirement Planning MRP One of the first software based integrated information systems designed to improve productivity for businesses A materials requirement planning MRP The central function of Material Requirements Planning MRP is to ensure material availability The quantities needed for production and sales must be procured in a timely manner To ensure this the MRP controller performs planning runs in the system Planning runs can be scheduled and executed automatically at regular recurring intervals

What Does MRP Stand For What Are The Differences Versus ERP Craftybase

https://craftybase.com/images/blog/post/what-does-mrp-stand-for-article.png

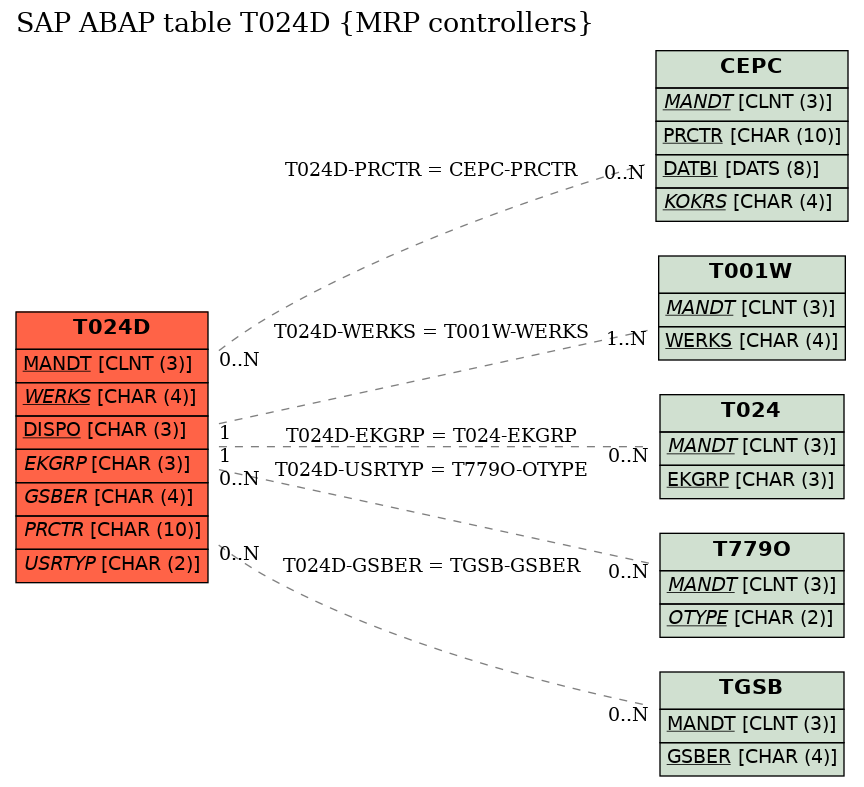

SAP ABAP Table Field T024D DSNAM Name Of MRP Controller SAP

https://www.sap-tables.org/table/t024d/sap-table-T024D-erd.png

What Is An Mrp Controller - Definition of MRP MRP is a system designed to plan manufacturing production It identifies necessary materials estimates quantities determines when materials will be required to meet the production schedule and manages delivery timing with the goal of meeting demands and improving overall productivity