What Can A 5 Axis Cnc Machine Do ROCHESTER HILLS MI August 27 2024 Global industrial automation leader FANUC America takes the machining world to the next level with the new FANUC Series 500i A CNC This new control series advances machine performance with 5 axis integrated technology and supports both machine tool builders and CNC users with their evolving needs including easier operations more security and

There s also two axis machining which can mill along the x and y axes and thus can mill in two direction left right or up down 3 2 vs 5 Axis CNC Machining For most parts 3 2 machining will do that job without any issues but sometimes you have parts that have more complex geometries That s when 5 axis shines Designed for 4 axis CNC milling machines it integrates a CNC motion controller and 4 high performance Trinamic stepper drivers into a single compact board This all in one design simplifies installation ensures seamless compatibility with a variety of stepper motors and saves valuable space by combining the Mach3 control card and stepper

What Can A 5 Axis Cnc Machine Do

What Can A 5 Axis Cnc Machine Do

https://cncpartsxtj.com/wp-content/uploads/2022/03/5-axis-cnc-5-axis-cnc-machine-5-axis-cnc-machines-5-axis-mill-5-axis-milling-machine-1-scaled.webp

The Future Of Industrial Manufacturing 3 Axis And 5 Axis CNC Milling

https://www.cavitymold.com/wp-content/uploads/2021/08/5-Axis-CNC-Milling-Machines.png

5 Axis CNC Routers 5 Axis CNC Router Machines For Sale

https://i0.wp.com/www.cncpd.com/wp-content/uploads/2018/10/DMS-5-Axis-CNC-Router-E515-03.jpg?fit=1400%2C1050&ssl=1

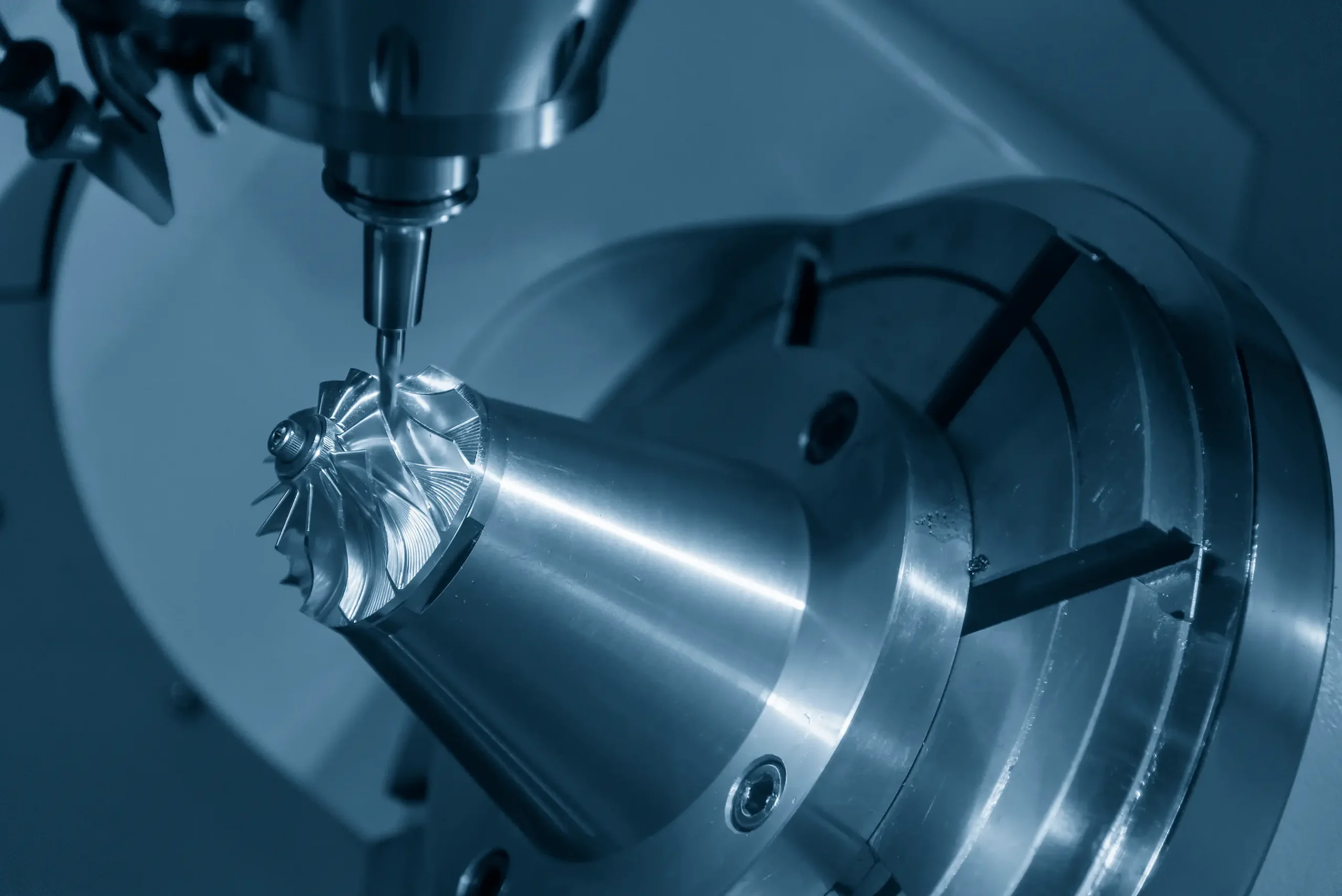

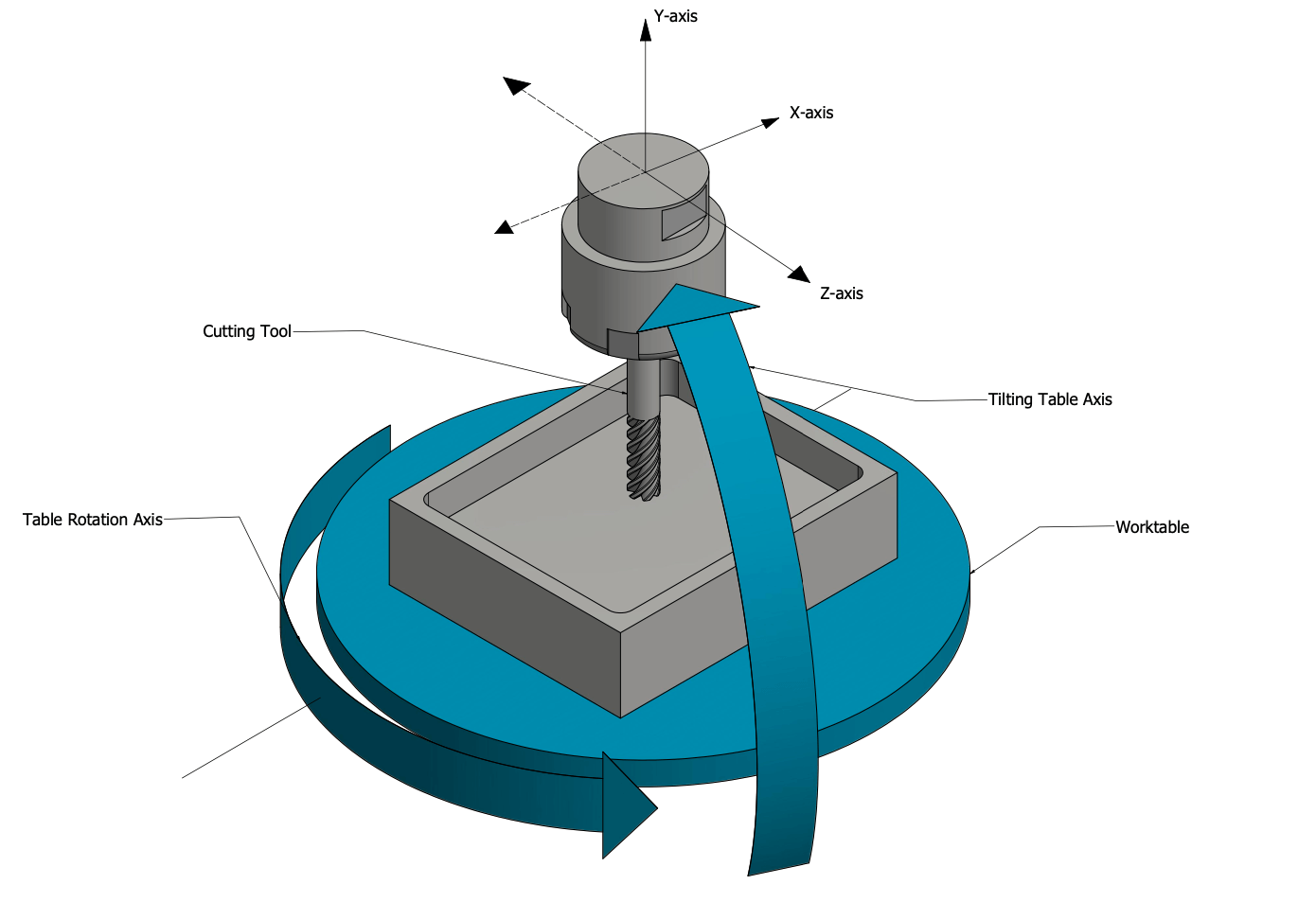

A 5 axis CNC machine allows the machining of five surfaces simultaneously For conventional 3 axis machining you may need several setups to work on parts with several faces But the 5 axis technology completes the machining of contoured parts and other parts with many faces in a single structure How 5 Axis Machining Works At the heart of 5 axis CNC milling lies the ability to achieve simultaneous motion along five axes X Y Z and two rotational axes typically A and B The A axis rotates around the X axis while the B axis rotates around the Y axis This combination of movement allows the tool to tilt and swivel facilitating

The incredible 5 axis ma in this video we ll look at an example of a 5 axis CNC machining video to understand what 5 axis CNC machining is and how it works 5 axis CNC machining is a suitable method for hook surface machining unusual shape machining hollow machining oblique hole etc While 5 sided machining is similar to but more capable than 3 axis machining It can only process five sides but would fail to achieve some special machining in one single set up

More picture related to What Can A 5 Axis Cnc Machine Do

APEC 5 axis High Speed Milling Machine Fermatsweden

http://fermatsweden.se/wp-content/uploads/2017/03/G-series-1.jpg

Affordable 5 Axis CNC Milling Machine Center Expand Machinery

https://www.expandmachinery.com/wp-content/uploads/2020/12/Ganesh-GenMill-5X-12-5-Axis-Simultaneous-CNC-Milling-Machine-Center-1280x854.jpg

How Does A 5 Axis CNC Machine Work

https://www.china-machining.com/wp-content/uploads/2021/10/understand-5-axis-CNC-1.png

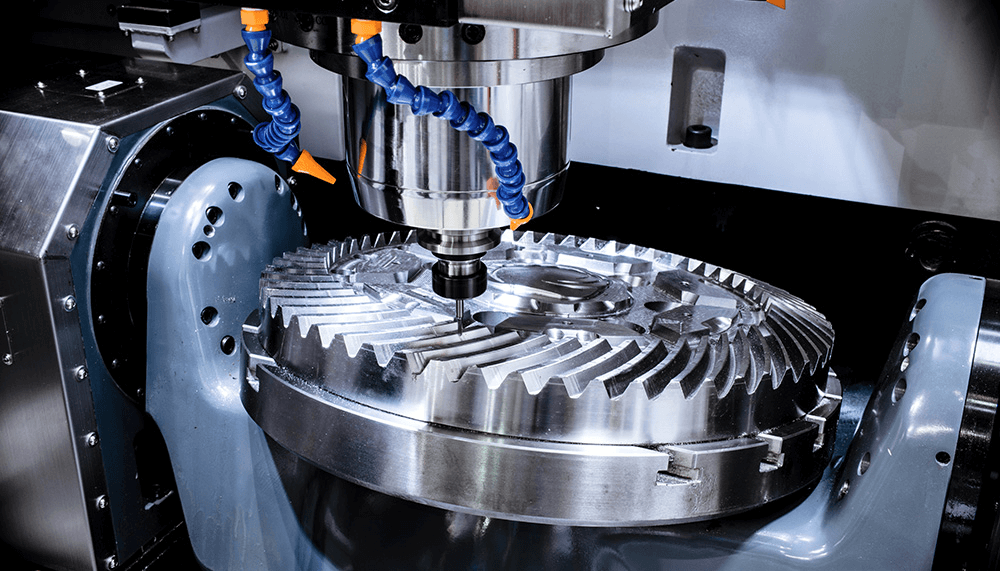

The A B and C axes are ordered alphabetically to correspond with the X Y and Z axes Although there are 6 axis CNC machines such as Zimmermann s FZ 100 Portal milling machine 5 axis configurations are more common since adding a sixth axis typically offers few additional benefits One last note about axis labeling conventions in a vertical machining center the X and Y axes reside in 5 High Production Efficiency The 5 axis machining can effectively reduce the machining time and auxiliary time of the parts It has a large range of spindle speed and feeds rage allowing the machine to perform a powerful large cutting capacity 5 axis CNC is entering an era of high speed machining

However 5 axis CNC machines introduce two additional rotational axes often called the A and B axes These axes let the workpiece or tool rotate allowing for more intricate and precise cuts Picture a sculptor who can seamlessly maneuver around a sculpture instead of just carving from one angle ensuring each detail is meticulously crafted The 5 axis CNC machining process starts with the designer creating a 3D CAD computer aided design model of the desired part using CAD tools like SolidWorks and Autodesk Inventor Next the machinist exports this CAD model into a CAM computer aided manufacturing software which converts the drawing into a computer program also called G code

4 Axis CNC Machining Trace A Matic

https://www.traceamatic.com/4-axis-cnc-machining/4-axis-cnc-machining-1000.jpg

What Is 5 Axis CNC Machining 5 Axis CNC Service

https://global-uploads.webflow.com/62b58ca8abc6088f2afd1f66/62e3b69a138cd3896c1c141a_shutterstock_1107871796-1024x683.jpeg

What Can A 5 Axis Cnc Machine Do - 5 axis CNC machining is a suitable method for hook surface machining unusual shape machining hollow machining oblique hole etc While 5 sided machining is similar to but more capable than 3 axis machining It can only process five sides but would fail to achieve some special machining in one single set up