What Is The Purpose Of Quality Control Quality control is a process through which a business seeks to ensure that product quality is maintained or improved and manufacturing errors are reduced or eliminated Quality control requires

Quality control extends to managing the quality of materials and components obtained from suppliers This means assessing supplier capabilities conducting audits and establishing quality agreements to ensure that all inputs meet the standards 10 Documentation and Record Keeping Quality control is important because it can Encourage quality consciousness Quality control encourages employees to keep quality in mind throughout the manufacturing process which can help the company achieve the desired level of quality each time Lower production costs The process used for quality control checks the production of items

What Is The Purpose Of Quality Control

What Is The Purpose Of Quality Control

http://www.quotemaster.org/images/13/1313c4059e03607694eb717f16c50fff.png

Purpose Of A Quality Management System QMS

https://lincoln-edu.ae/wp-content/uploads/2018/11/Purpose-Of-Quality-Management.jpg

Ecologic n Fa a Creator Quality Control Diagram Dual Bibliotecar

https://content.dcf.ks.gov/ees/KEESWebHelp/NonMedical-KEESWebHelp/image162.gif

Quality control encourages employees to adopt a quality mindset throughout the manufacturing process creating an environment conducive to consistently producing a quality product It boosts customer satisfaction Quality control ensures that customers receive error free products increasing overall customer satisfaction Quality Control QC is an indispensable aspect of various industries ensuring that products and services adhere to predefined standards In the manufacturing sector QC involves rigorous inspection and testing of raw materials intermediate components and final products to maintain consistent quality and minimize defects

The 7 Quality Control Tools Explained 1 Cause and Effect Diagram Fishbone Diagram The Cause and Effect Diagram also known as the Fishbone Diagram or Ishikawa Diagram is a powerful tool designed to facilitate root cause analysis and identify potential causes contributing to a specific problem or effect Quality control QC refers to all the actions a company takes to verify that their products meet specific quality standards According to ISO 9000 it is the part of quality management focused on fulfilling quality requirements and it generally involves inspections and testing Quality control focuses on the steps you take to identify

More picture related to What Is The Purpose Of Quality Control

BEST PRACTICES OF STATISTICAL PROCESS CONTROL SPC Kaizenindo Consulting

http://kaizenconsulting.co.id/wp-content/uploads/2020/12/quality.jpg

Quality Control Infographic 10 Steps Stock Vector Illustration Of

https://thumbs.dreamstime.com/z/quality-control-infographic-steps-quality-control-infographic-steps-concept-analysis-improvement-service-level-excellent-simple-158244736.jpg

Quality Assurance Chengdujinyan

http://chengdujinyan.com/wp-content/uploads/2019/07/quality-assurance-diagram-768x512.png

Quality control can be defined as part of quality management focused on fulfilling quality requirements While quality assurance relates to how a process is performed or how a product is made quality control is more the inspection aspect of quality management An alternate definition is the operational techniques and activities used to Quality inspector in a Volkseigener Betrieb sewing machine parts factory in Dresden East Germany 1977 Quality control QC is a process by which entities review the quality of all factors involved in production ISO 9000 defines quality control as a part of quality management focused on fulfilling quality requirements This approach places emphasis on three aspects enshrined in

Quality Control QC is an indispensable component in product and service delivery playing a critical role in ensuring customer satisfaction maintaining brand reputation and enhancing overall business performance The commitment to maintaining high quality standards is essential in today s competitive market where customer expectations A quality management system QMS is defined as a formalized system that documents processes procedures and responsibilities for achieving quality policies and objectives A QMS helps coordinate and direct an organization s activities to meet customer and regulatory requirements and improve its effectiveness and efficiency on a continuous

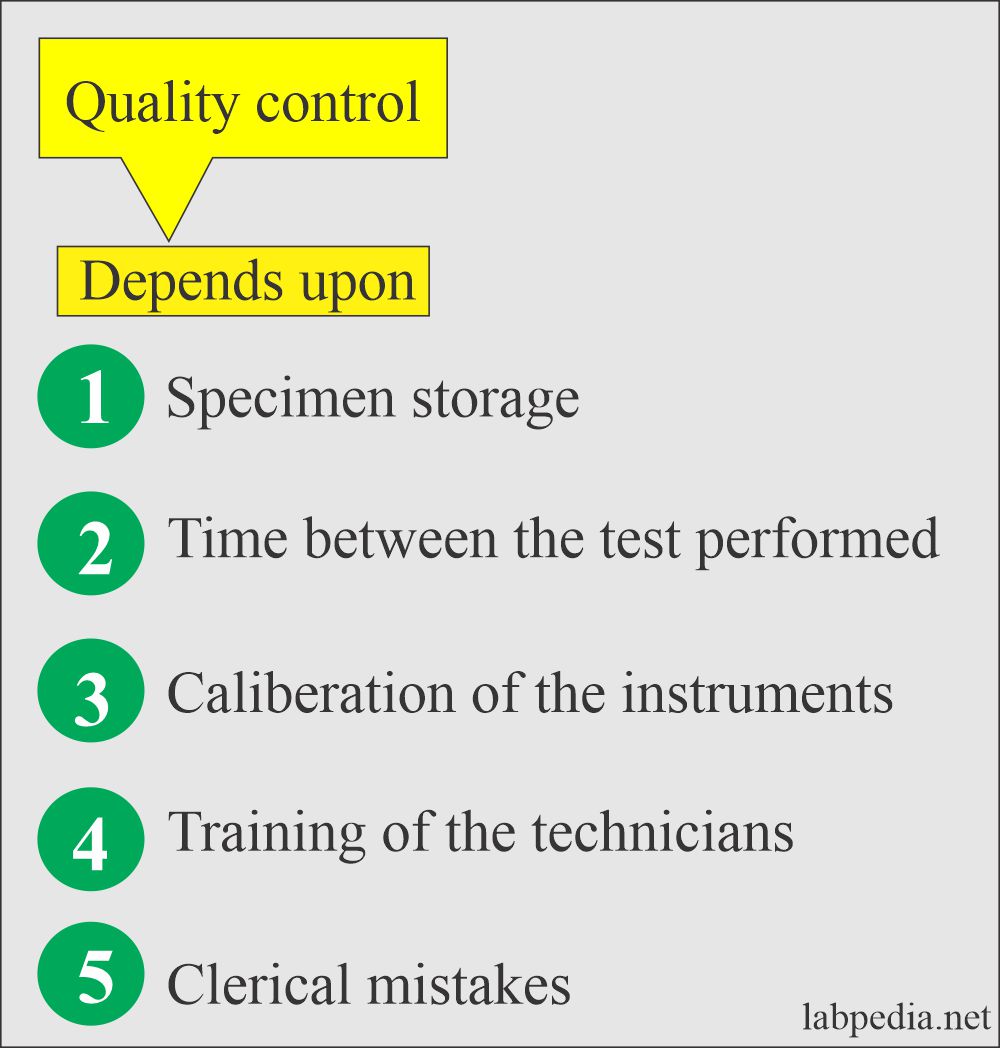

Quality Control QC Of The Clinical Laboratory Labpedia

https://labpedia.net/wp-content/uploads/2020/01/quality-control-2.jpg

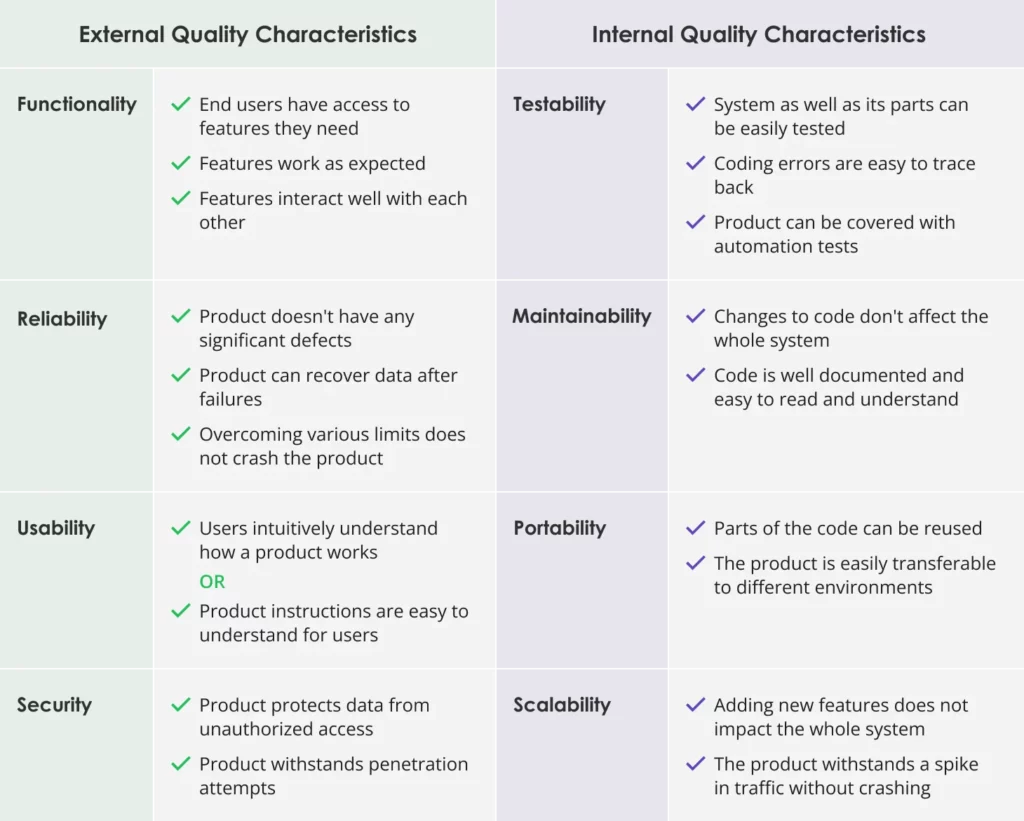

Quality Assurance Vs Quality Control Key Differences Edvantis

https://www.edvantis.com/wp-content/uploads/2022/11/QA-1024x821.webp

What Is The Purpose Of Quality Control - Quality Control QC is an indispensable aspect of various industries ensuring that products and services adhere to predefined standards In the manufacturing sector QC involves rigorous inspection and testing of raw materials intermediate components and final products to maintain consistent quality and minimize defects