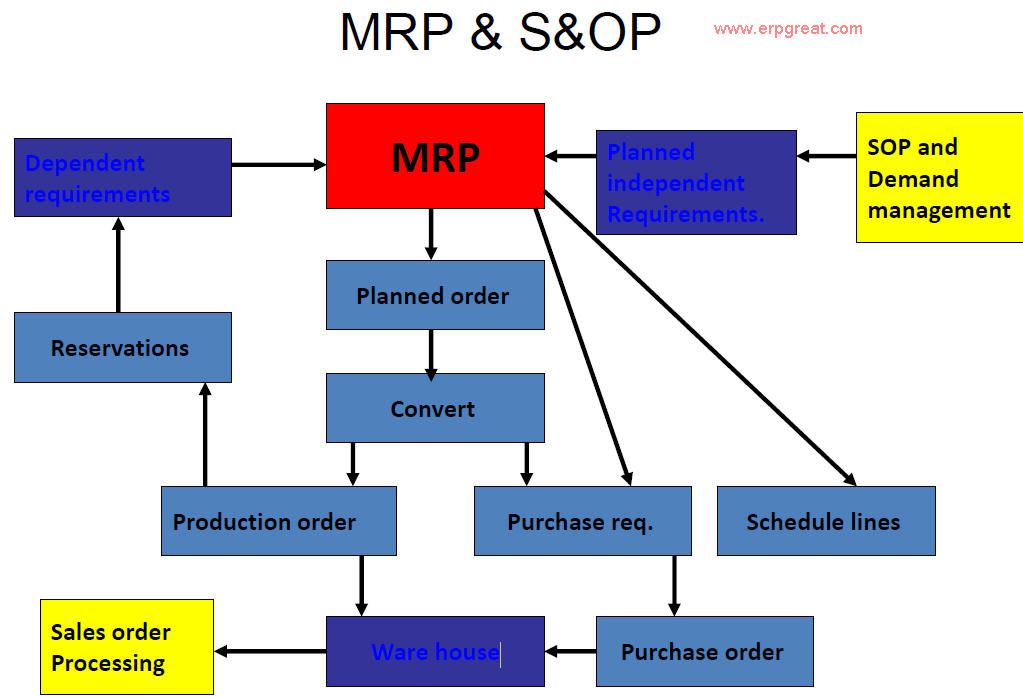

What Is Bom In Mrp Using the BOM and the MPS for all the products the MRP run will step by step calculate the assemblies components and materials that must be produced or purchased over the planning period Next it checks the needed quantities against available inventory called netting to identify net shortages for each component

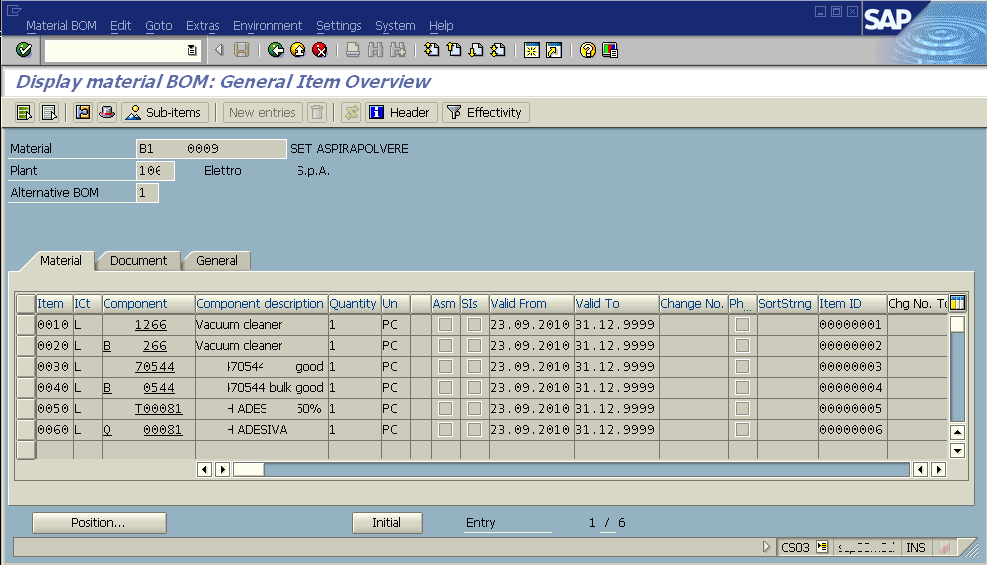

2 Key Components of MRP a Bill of Materials BOM Definition A hierarchical structure listing all components sub assemblies raw materials and parts required to produce a product Purpose Helps identify the quantities of materials needed at each stage of production b Master Production Schedule MPS Definition A detailed plan that outlines what needs to be produced in what quantities An engineering BOM is not always the same as the manufacturing BOM or MRP BOM The engineering BOM states exact quantities of parts or ingredients inside the product including the detailed assembly structure of the product Often does not reflect everything that is actually consumed during production

What Is Bom In Mrp

What Is Bom In Mrp

https://i.ytimg.com/vi/-BjQrUJSn1M/maxresdefault.jpg

Step by step Mrp Calculation Process YouTube

https://i.ytimg.com/vi/lDYPbG9Au9I/maxresdefault.jpg

What Is The Material Requirement Planning MRP MRP Process YouTube

https://i.ytimg.com/vi/u3P6YMI5Ah0/maxresdefault.jpg

The MRP system then calculates the total component requirements adapted to the planned production schedule that was created using the BOM information Inventory check is the next important step MRP compares the calculated material requirements to current inventory levels to identify any possible shortages Material requirements planning MRP is a production planning scheduling and inventory control system used to manage manufacturing processes The bill of materials BOM specifies the relationship between the end product independent demand and the components dependent demand MRP takes as input the information contained in the BOM

The BOM determination in MRP is done level by level through the structure above and by the procedure below Here is the detail of the steps Step 1 Determine the BOM usage The usage is determined by the selection ID which can be configured in customizations below In the MRP customization the selection ID to be used is defined on plant level When the BOM is stored within the MRP system this allows quality control personnel to view the most current information on a product s makeup 6 Effective Change Management It s common to find firms managing engineering change management ECM operations within MRP systems That means organizations can efficiently manage changes to

More picture related to What Is Bom In Mrp

Materials Requirement Planning MRP Inputs Outputs Of MRP

https://i.ytimg.com/vi/poOz3ZlJEtg/maxresdefault.jpg

What Is BOM What Is Bill Of Material What Is BOM In Industry How

https://i.ytimg.com/vi/jchC2Hx7hnM/maxresdefault.jpg

MRP Top Priority Systems

https://i1.wp.com/topprioritysystems.com/wp-content/uploads/2015/09/MRP.png

MRP helps in creating a detailed production plan to ensure material availability by aligning inventory levels with actual demand helping businesses avoid surpluses and shortages MRP breaks production into detailed steps using a bill of materials BOM and generates master production schedules for accurate timelines By tracking inventory This BOM is commonly based on a computer aided design CAD drawing MRP BOM Displays A BOM displays its information in one of two ways an explosion display or an implosion display An

[desc-10] [desc-11]

SOP Diagram

https://www.erpgreat.com/production/mpr-sop.jpg

Sap Bom Tables Brokeasshome

http://www.kodyaz.com/images/sap-abap/sap-cs03-display-material-bom-general-item-overview-screen.PNG

What Is Bom In Mrp - Material requirements planning MRP is a production planning scheduling and inventory control system used to manage manufacturing processes The bill of materials BOM specifies the relationship between the end product independent demand and the components dependent demand MRP takes as input the information contained in the BOM