What Did A Millwright Do In The 1800 Millwright History The millwright of the 17th and 18th centuries was quite different from the millwright of today He was a master craftsman who completely designed and constructed mills Water was the only natural power source of the day and James Watt had only just perfected the steam engine by the mid 18th century Water was directed over

A millwright is a craftsman or skilled tradesman who installs dismantles maintains repairs reassembles and moves machinery in factories power plants and construction sites 1 The term millwright also known as industrial mechanic 2 is mainly used in the United States Canada and South Africa to describe members belonging to a particular trade Other countries use different terms The 1911 census identified just 2 400 millwrights a decrease of c 7 500 in the 60 years between 1851 and 1911 The decline of traditional millwrights from the mid 19 th century could be attributed to the advances in milling technology stimulated by the need to feed a rapidly growing urban population

What Did A Millwright Do In The 1800

What Did A Millwright Do In The 1800

https://emke.uwm.edu/wp-content/uploads/2018/03/IMG_2439-2.jpg

ship - Shipping in the 19th century | Britannica

https://cdn.britannica.com/79/149579-050-CD88F327/John-Wood-English-oil-canvas-Bombay-India-1850.jpg

The Budd Company: An Industrial Icon That Broke

https://hiddencityphila.org/wp-content/uploads/2018/08/Workers-pose-at-their-stations-in-a-workshop.-Jigs-can-be-seen-on-each-table..jpg

5 In 1791 Washington was one of the first mill owners to install the Evans automated system During Washington s presidency a millwright and engineer named Oliver Evans developed an automated milling system that was subsequently submitted to the new US Patent Office Evans developed an advanced system where the bucket elevator was designed to move grain and flour through the mill without The traditional miller needed the skills of a millwright for the dressing and setting up of millstones critical to efficient usage Different stones were used for different seeds such as barley wheat oats rye or beans and for different products such as animal feeds or flour The most widely used were the gritstones from the Peak District of north Derbyshire but French stones were

Windmills began to fade with the development of steam power in the 1800s and went into rapid retreat in the twentieth century with the perfection of the internal combustion engine and electrical motors Major repairs required a millwright Most millers however probably could stitch a sail or fix a slight gear problem Black said Post medieval mills and milling 1540 1750 From Quern to Computer a history of flour milling by Martin and Sue Watts covers a wide range of topics and this summarises Chapter 8 This period to the mid 18th century saw significant developments in the technology of corn milling changes in land ownership and a rise in population as standards of

More picture related to What Did A Millwright Do In The 1800

Surfing Amber Waves of Grain, Part II | Edible Marin & Wine Country

https://ediblemarinandwinecountry.ediblecommunities.com/sites/default/files/surfing-amber-waves-1.jpg

PDF) The Wheels of Change: Human Capital, Millwrights, and Industrialization in Eighteenth-Century England *

https://i1.rgstatic.net/publication/337332236_The_Wheels_of_Change_Human_Capital_Millwrights_and_Industrialization_in_Eighteenth-Century_England/links/5dd2c4c7a6fdcc7e138d1a46/largepreview.png

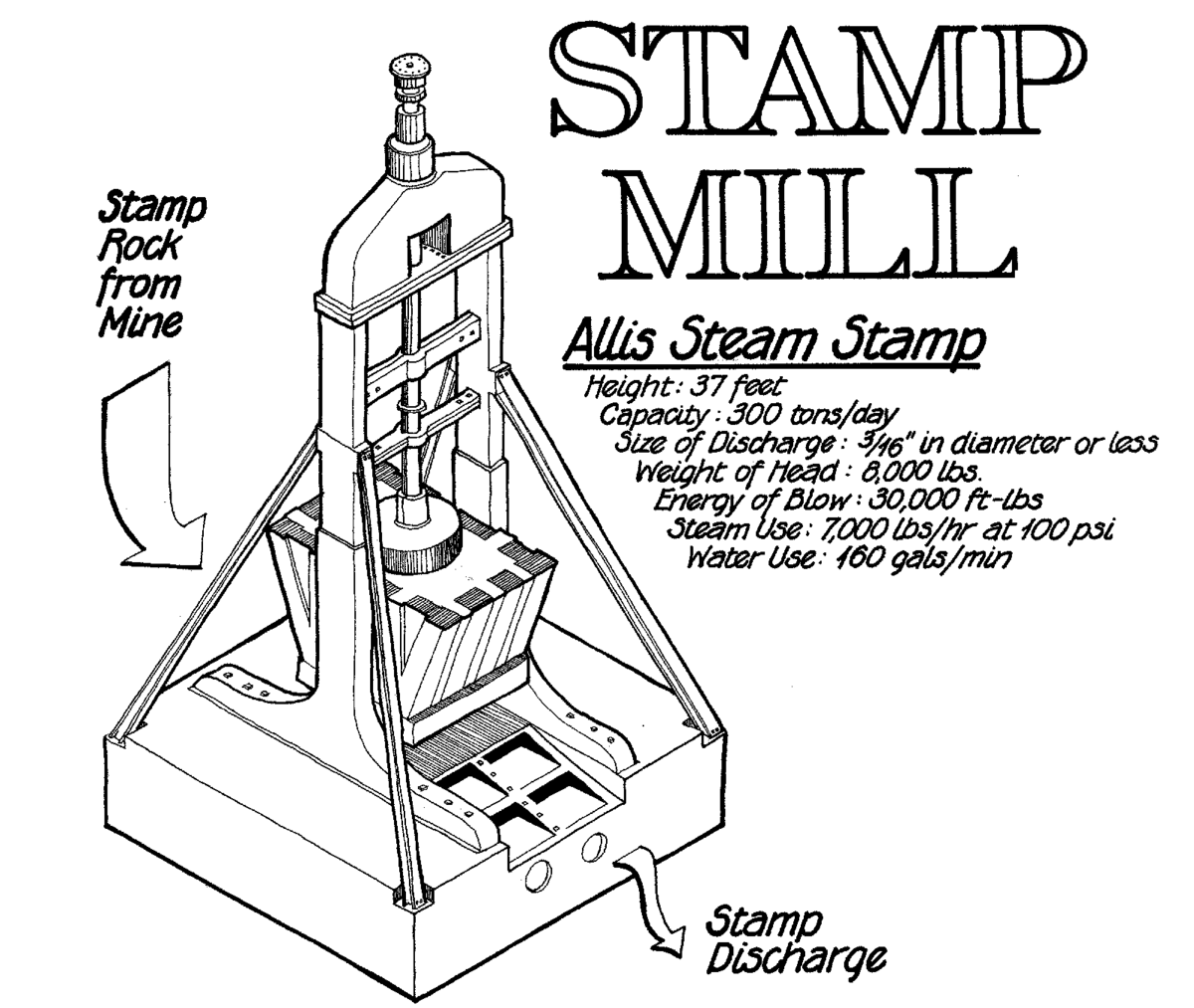

Stamp mill - Wikipedia

https://upload.wikimedia.org/wikipedia/commons/thumb/c/cb/LOC_MI0086_QuincyMine_TIF_00027a_cropStampMill.png/1200px-LOC_MI0086_QuincyMine_TIF_00027a_cropStampMill.png

The consensus among economic historians has been that Britain s leadership during the Industrial Revolution owed little to the school system But recent work on human capital suggests that we should rethink this consensus on the role of human capital This column shows how millwrights highly skilled carpenters who specialised in constructing and repairing watermills had a persistent Laws regulated the prices millers could charge for their services and protected other landholders from flooding and other potential problems a mill might cause Fast moving streams powered early mills A natural or man made waterfall poured down the water that turned the waterwheel next to the mill building The right amount of water was crucial

A few years at that mill led me to another historic site Stratford Hall which is an 18th century house with a restored mill that I operated and helped a millwright restore again When the position opened up here at Mount Vernon in 2007 they were restoring the distillery and the gristmill was running they needed somebody to manage the site The millwright found a good site Foundation walls were erected Logs were cut and fashioned into beams boards and shingles Pillars were constructed to support the water wheel shaft Mill millwright located a white oak tree for the water wheel shaft Only the millwright had the knowledge of what woods were best used for different parts

PDF) The Wheels of Change: Technology Adoption, Millwrights, and Persistence in Britain's Industrialization

https://i1.rgstatic.net/publication/340971714_The_Wheels_of_Change_Technology_Adoption_Millwrights_and_Persistence_in_Britain's_Industrialization/links/5ea81fb6299bf1dcb09ebbd8/largepreview.png

The Gristmill: Creating Meal, Flour & Roads - Moving North Carolina

https://movingnorthcarolina.net/wp-content/uploads/2020/04/Gristmills-featured-pic.jpg

What Did A Millwright Do In The 1800 - The traditional miller needed the skills of a millwright for the dressing and setting up of millstones critical to efficient usage Different stones were used for different seeds such as barley wheat oats rye or beans and for different products such as animal feeds or flour The most widely used were the gritstones from the Peak District of north Derbyshire but French stones were