How To Calculate Cnc Machine Hour Rate In Excel Section 2 Setting Up the Excel Spreadsheet Introduction to Excel for CNC Machine Hour Rate Calculations Creating the Basic Structure of the Spreadsheet Data Entry Gathering Necessary Information Section 3 Calculating Fixed Costs Identifying and Categorizing Fixed Costs Allocating Fixed Costs to Each Machine

3 3 Tool Changeover Time 3 4 Machine Downtime Chapter 4 Calculating CNC Machine Hour Rate 4 1 Determine Total Annual Fixed Costs 4 2 Calculate Total Machine Operational Hours 4 3 Calculate Total Variable Costs 4 4 Divide Total Costs by Total Machine Hours Chapter 5 Considerations for Accuracy The CNC machine hourly rate calculator is a crucial tool for shops looking to accurately estimate the costs of CNC machining jobs This calculator takes into account various factors including the machine s total cost of ownership the operator rate working hours per day downtime percentage and markup By inputting these details shops can

How To Calculate Cnc Machine Hour Rate In Excel

How To Calculate Cnc Machine Hour Rate In Excel

https://i.ytimg.com/vi/LL-tpsk7l-0/maxresdefault.jpg

CNC Machine Wallpapers Wallpaper Cave

https://wallpapercave.com/wp/wp10869048.jpg

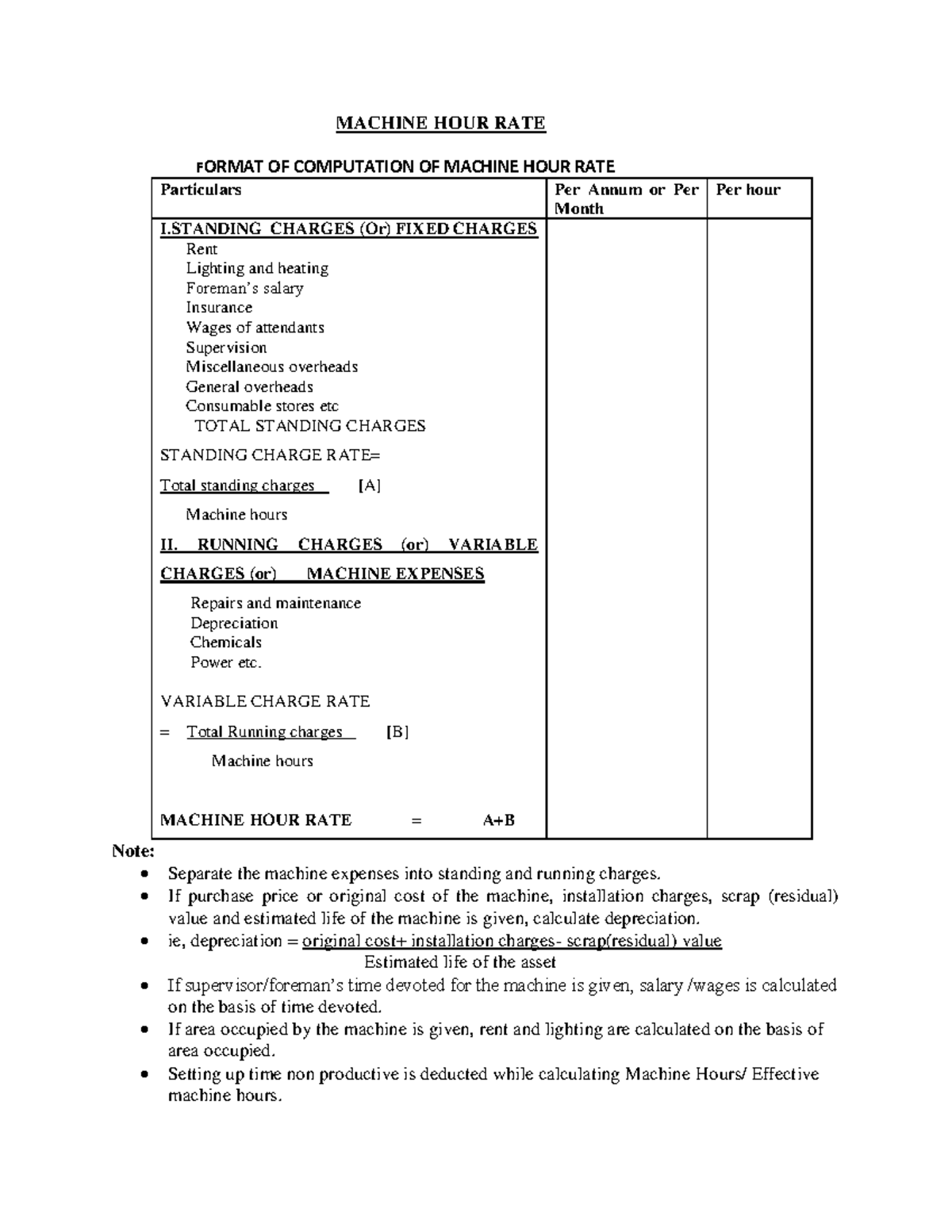

Machine Hour Rate Machine Hour Rate Cost Accounting Meaning Of

https://i.ytimg.com/vi/zl22VYFSePg/maxresdefault.jpg

To accurately estimate the cost of CNC machining it is essential to calculate the machine hour rate effectively This calculation takes into account various factors such as labor costs machine depreciation overhead expenses and material costs We will break down each element and discuss how to calculate them accurately The hourly rates of standing charges and running charges will be aggregated to obtain the machine hour rate Example From the following information compute the machine hour rate for Machine No 51 for the month of January 2019 Cost of machine 6 000 Estimated scrap value 1 000 Effective working life 5 000 Hours Hours worked in January

Quick video tutorial on how to calculate your CNC Machine s Hourly Rate using the G Wizard Calculator CNC Machine Costs Two factors influence machining expenses the upfront cost of a CNC machine and its expected yearly usage typically around 5000 hours Machinists determine machine shop rates commonly known as the machining charge per hour by dividing the price of CNC machines by their total yearly usage hours

More picture related to How To Calculate Cnc Machine Hour Rate In Excel

Machine HOUR RATE MACHINE HOUR RATE FORMAT OF COMPUTATION OF MACHINE

https://d20ohkaloyme4g.cloudfront.net/img/document_thumbnails/4e1df6d1a546029ec452b60343bee96d/thumb_1200_1553.png

Calculate Machine Hour Rate Cost Of The Machine Rs 11000 Scrap Value

https://hi-static.z-dn.net/files/d7c/da0746ec28683cf488c871ce03e3709b.png

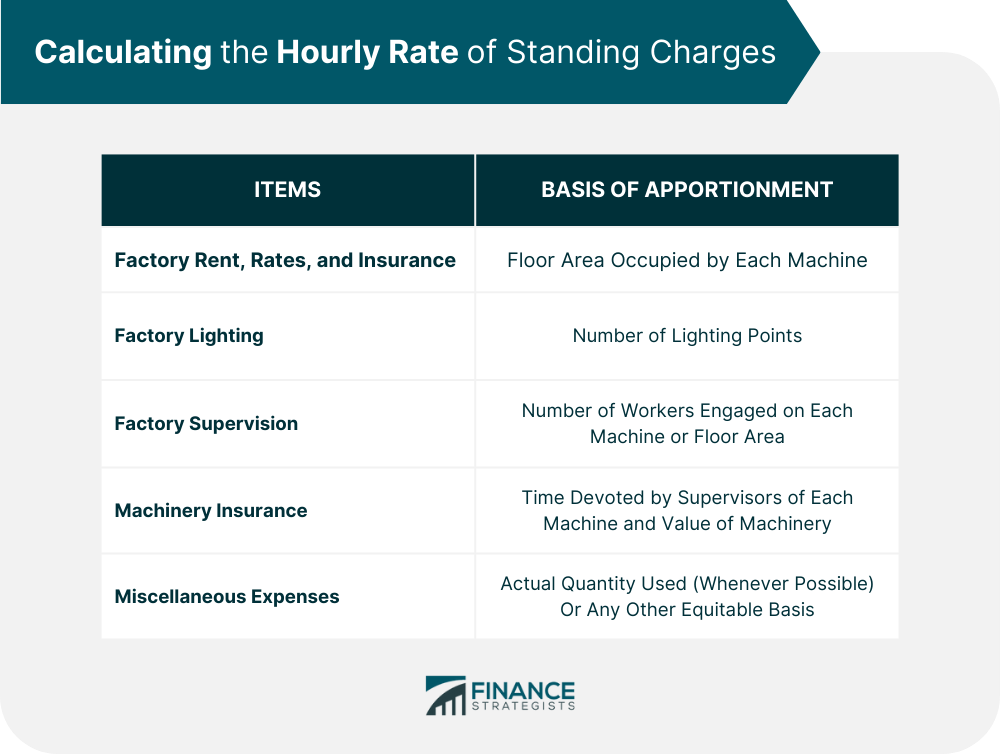

Calculating The Machine Hour Rate Finance Strategists

https://www.financestrategists.com/uploads/Calculating-the-Hourly-Rate-of-Standing-Charges-1.png

For pricing a CNC work first estimate the fixed costs machine cost tool power interest the variable costs material labor and other costs design Add a markup of 10 30 to the total cost fixed costs variable costs design cost to get the price for your CNC work In the next sections we ll go into the detail of how to do this Calculate the annual costs of these then divide by total labor or machine hours for the year This will be your overhead cost per hour Once the above costs are calculated you can use the formulas and guidelines below to arrive at either a general shop hourly rate or an hourly rate based on a specific piece of equipment

CNC machining cost calculations and formula for machine hours rate calculations Machine Utilization Productive Machine Hours Scheduled Machine Hours x 100 Below are a few examples of how to calculate machine utilization rate If a machine in a single shift CNC facility is scheduled to run eight hours a day Monday through Friday and due to setups cleaning breakdowns and other operating tasks only runs for a

CNC Machine Hourly Rate Calculator CNCCookbook CNCCookbook Cnc

https://i.pinimg.com/originals/0b/7b/92/0b7b925295ba43c216854d74a4b24bf9.jpg

How To Calculate MAPE With Zero Values simply Explained

https://stephenallwright.com/content/images/size/w1384/2022/07/How-to-calculate-MAPE-with-0-values.png

How To Calculate Cnc Machine Hour Rate In Excel - To accurately determine the CNC machine hour rate it is crucial to consider various components that contribute to the overall cost This section will explore the key elements that comprise the machine hour rate including fixed costs variable costs and machine utilization 2 Determining Fixed Costs